We are building our manufacturing capabilities across geographies and addressing emerging market requirements with swiftness and precision.

Currently, we are catering to Bangladesh markets through the export of over 12 popular motorcycles and scooters, which are marketed through 195 outlets across the country.

Our second overseas plant is coming up in Bangladesh, which we are building in joint venture (JV) with ‘Nitol Niloy Group’ of Bangladesh. This plant will commence operations in 2017-18. The upcoming plant is located in Jessore, Bangladesh with an initial annual capacity of 150,000 units.

During FY 2016-17, we launched an Eid campaign across our outlets, leading to the sales of 10,000+ two-wheelers in June, making us the No. 1 player during that period.

In the current financial year, our state-of-the-art facility in Villa Rica near Cali in Colombia stabilised its operations. The plant is operating at a production capacity of 80,000 units per annum. It will be expanded to produce 150,000 units annually, in the next phase.

Currently, the facility is producing eight models from our range of products. Hero is also the only two-wheeler manufacturer to offer 4-year warranty on all its models in Colombia.

This plant will gradually act as a hub for selling to the Andean countries (Bolivia, Colombia, Ecuador and Peru). It has the potential also to be a strategic base for shipping to North American markets, such as Mexico and the US in the future.

We are selling our products through a network of 195 outlets spread across 133 cities and towns in the country.

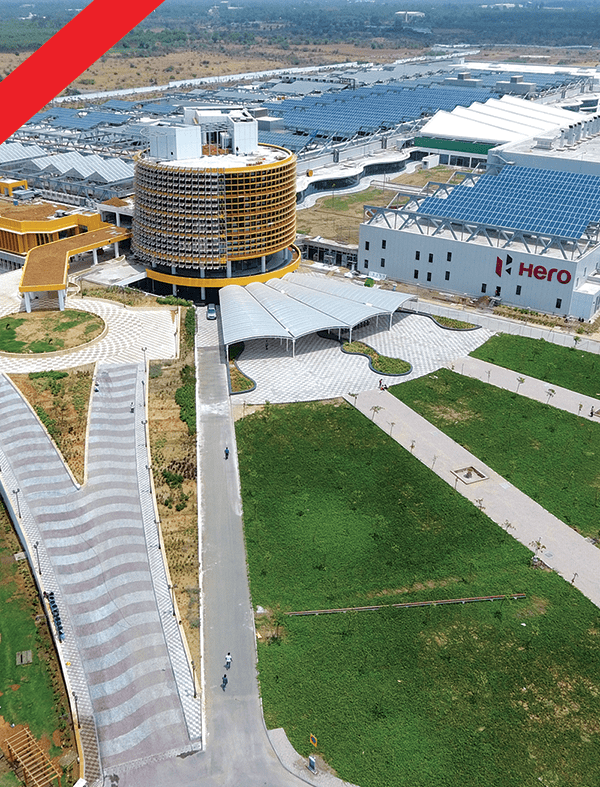

We commenced commercial production at our Vadodara plant during this year. The first manufactured product from the plant (Splendor Pro) was offered to the Somnath Temple Trust. The first phase capacity of Vadodara plant will have a capacity of 1.2 million units annually. Gradually, the overall production capacity will be increased to 1.8 million units annually.

We have planned a capital expenditure of around ` 2,500 crores up to FY 2019 towards new product development, digitisation, phase-wise capacity installation and expansion at our existing as well as at our upcoming facilities in Andhra Pradesh and Bangladesh. The CAPEX also includes investments towards upgradation and modernisation of plant machinery.

` 0 cr