210 cc engine

100% of our facilities are ISO 45001 certified

210 cc

4 Stroke 4 Valve Single Cylinder Liquid Cooled DOHC

280mm | 270mm

Rear and Front suspension travel

250 cc

4 Stroke, 4 Valve, Single Cylinder Liquid Cooled, DOHC

25 nm

@7250 RPM

210 cc

4 Stroke 4 Valve Single Cylinder Liquid Cooled DOHC

20.7 nm

@7250 RPM

97.2 cc

Air cooled, 4-stroke, Single cylinder, OHC

8.05 nm

@6000 RPM

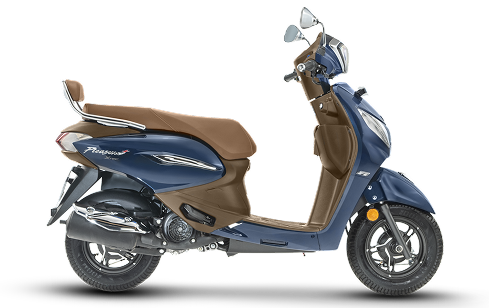

124.7 cc

Air Cooled, 4-Stroke, OHC, Single Cylinder

10.6 nm

@6000 RPM

163.2 cc

Air oil cooled, 4-stroke, Single cylinder, OHC

14.6 nm

@6500 RPM

199.6 cc

Oil Cooled, 4 stroke 4 Valve single cylinder OHC

17.35 nm

@6500 RPM

440 cc

Air cooled, 4-stroke, Single cylinder, OHC

38 nm

@4000 RPM

440 cc

Air cooled, 4-stroke, Single cylinder, OHC

38 nm

@4000 RPM

210 cc engine

250 cc engine

210 cc engine

97.2 cc engine

97.2 cc engine

97.2 cc engine

97.2 cc engine

97.2 cc engine

97.2 cc engine

125 cc engine

125 cc engine

125 cc engine

124.7 cc engine

163.2 cc engine

163.2 cc engine

199.6 cc engine

210 cc engine

440 cc engine

440 cc engine

440 cc engine

210 cc

4 Stroke 4 Valve Single Cylinder Liquid Cooled DOHC

280mm | 270mm

Rear and Front suspension travel

250 cc

4 Stroke, 4 Valve, Single Cylinder Liquid Cooled, DOHC

25 nm

@7250 RPM

210 cc

4 Stroke 4 Valve Single Cylinder Liquid Cooled DOHC

20.7 nm

@7250 RPM

97.2 cc

Air cooled, 4 stroke

8.05 nm

@6000 RPM

97.2 cc

Air cooled, 4-stroke, Single cylinder, OHC

8.05 nm

@6000 RPM

97.2 cc

Air cooled, 4-stroke, Single cylinder, OHC

8.05 nm

@6000 RPM

97.2 cc

Air cooled, 4-stroke, Single cylinder, OHC

8.05 nm

@6000 RPM

97.2 cc

Air cooled, 4-stroke, Single cylinder, OHC

8.05 nm

@6000 RPM

97.2 cc

Air cooled, 4-stroke, Single cylinder, OHC

8.05 nm

@6000 RPM

125 cc

Air cooled, 4-Stroke

10.5 nm

@6500 RPM

125 cc

5.7 sec, Acceleartion 0-60kmph

10.5 nm

@6500 RPM

125 cc

Air cooled, 4-stroke, Single cylinder, OHC

10.6 nm

@6000 RPM

124.7 cc

Air Cooled, 4-Stroke, OHC, Single Cylinder

10.6 nm

@6000 RPM

163.2 cc

Air oil cooled, 4-stroke, Single cylinder, OHC

14.6 nm

@6500 RPM

163.2 cc

Air Cooled 4 stroke

14 nm

@6500 RPM

199.6 cc

Oil Cooled, 4 stroke 4 Valve single cylinder OHC

17.35 nm

@6500 RPM

210 cc

Liquid cooled, 4-stroke, Single cylinder, OHC

20.4 nm

@4000 RPM

440 cc

Oil cooled, 4-stroke, Single cylinder, OHC

36 nm

@4000 RPM

440 cc

Air cooled, 4-stroke, Single cylinder, OHC

38 nm

@4000 RPM

440 cc

Air cooled, 4-stroke, Single cylinder, OHC

38 nm

@4000 RPM

110 cc engine

125 cc engine

156 cc engine

124.6 cc engine

124.6 cc engine

110.9 cc engine

110.9 cc engine

110 cc

Air Cooled, 4 stroke engine

8.7 nm

@5750 RPM

125 cc

Air cooled, 4 stroke, SI engine

10.4 nm

@5500 RPM

156 cc

Liquid cooled, 4 Valve single cylinder SOHC

14 nm

@6250 RPM

124.6 cc

Air Cooled, 4 stroke, SI

10.4 nm

@6000 RPM

124.6 cc

Air Cooled, 4-Stroke, SI Engine

10.36 nm

@5500 RPM

110.9 cc

Air cooled, 4-stroke, SI engine

8.70 nm

@5750 RPM

110.9 cc

Air cooled, 4-stroke Single Cylinder OHC

8.70 nm

@5500 RPM

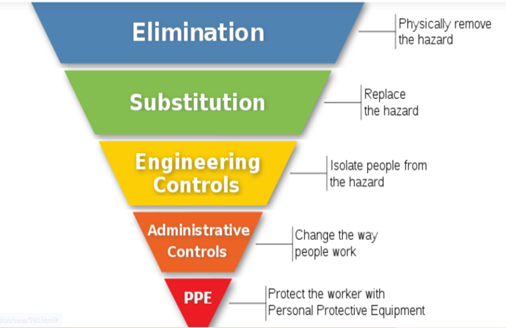

The OHS Management is a comprehensive principle that prioritizes the creation of a healthy and safe work environment. This is designed to safeguard the health and safety of all stakeholders i.e., External and Internal regardless of their employment status.

We have developed programs that not only comply with the legal and other requirements but also adhere to the international standards and requirements based on the certificates we have from the reputed organizations such as ISO- International Organization for Standardization, ILO- International Labour Organization, Five Star Health & Safety Standard from British Safety Council and World Health Organization-WHO.

These programs aim to promote wellness and safety in the workplace, preventing physical & psychosocial issues that can affect the overall well-being of our employees.

100% of our facilities are ISO 45001 certified

We have developed a comprehensive OHS program that sets the highest standard for occupational health and safety, in line with our commitment to the OHS policy, we have established an OHS management system designed to evaluate, monitor and continuously improve the health and safety practices.

Safety Committee:

We have formed joint committees at all levels, comprising representatives from all stakeholders, including employees, workers (both permanent and non-permanent), to ensure the effective functioning of programs and services that promote health and safety. These committees regularly evaluate and assess the effectiveness of our health and safety initiatives, identifying areas for improvement and planning for future enhancements.

Environment, Health, and Safety (EHS) Department:

We have established EHS departments at all our locations to prioritize the health and safety of our workforce. Functioning as a strategic partner, the departments facilitate risk management and ensure legal compliance in collaboration with our Safety Committees.

Hazard Identification & Risk Management:

The sections in the facilities do the risk management in coordination and assistance of Safety departments and cross-functional teams.

At the workplace for commencing any activity, the respective section head conducts the Hazard identification / spot the hazard at the workplace as per their work activities. Assess the risk and take the feasible controls for safely execution of the activity.

As an output of risk management, the HODs of the departments prepare the action plan to address the issues promptly and effectively. We have implemented various mechanisms to assess the risks including Hazard and Operability Study (HAZOP), Job Safety Analysis (JSA), Quantitative & Qualitative Risk Assessment (QRA), Pre- Task Assessment and Hazard identification and Risk Assessment (HIRA).

Procedure to Investigate Injuries, Hazards and Incidents:

To maintain a safe working environment, we follow a rigorous process to investigate workplace incidents. This procedure ensures we identify root causes and implement effective corrective actions to prevent future occurrences.

These steps ensure a thorough investigation and help in preventing future incidents by addressing the root causes and implementing corrective actions.

Safety Inspection and audit system:

We have a robust mechanism of internal and external inspections & audits throughout the year, guided by a comprehensive safety audit matrix. This ensures due diligence and maintains the health and safety system across our workplaces.

Concerned agencies are required to submit an Action Taken Report (ATR) following the closure of any observations identified through the hazard notification portal or other channels. These reports are systematically followed up by the escalation matrix before the due dates of closer action.

We have set ambitious targets to achieve a zero-incident culture. To support this goal, we continually strive to enhance our Occupational Health and Safety (OHS) management system through leadership commitment and stakeholder engagement.

Our focus remains on defining safety metrics, conducting rigorous risk and hazard assessments, and ensuring compliance through regular internal and external audits.

MOC (Management of Change):

We use MOC for the analytical review and approval of changes to the documented process technology and/or facilities, considering potential hazards being introduced to the process, system, or operation, and their elimination or control.

We conduct risk analyses using techniques like JSA, HAZOP and QRA to identify hidden risks and prevent incidents.

Bench marking of best practices:

We benchmark Health & Safety best practices by conducting cross-plant visits, engaging in inter-industry exchanges, and analyzing outputs from safety review meetings. Based on these insights, we develop structured action plans to ensure the horizontal deployment of learnings across all our facilities.

Monthly Safety Campaigns & Promotional Activities:

Hero MotoCorp is committed to providing safe and healthy working conditions to its employees and other persons who may be affected by its operations.

To uphold this commitment, the Environment, Health & Safety (EHS) department conducts monthly safety campaigns featuring various promotional activities, including training sessions, inspections, skits, 'hazard hunts', interactive 'Chalta-Bolta' quizzes, spot the Hazard etc. These initiatives require meticulous planning and continuous engagement with both internal and external stakeholders.

Beyond these monthly campaigns at our facilities, we also conduct promotional campaigns /events like National Safety Month, Fire service week, Road Safety Month, World food safety day, Electrical Safety Week etc.

Behaviors Observation system:

The behavior observation system in the workplace is implemented through safety audits, inspections, and monitoring. The purpose of this process is to proactively identify unsafe actions and conditions in the plant and plan appropriate countermeasures. This helps ensure a safe and accident-free workplace by checking and verifying workplace conditions for any safety deviations and potential hazards. The objectives include identifying potential hazards, assessing the risk involved in the plant, and recommending measures for improving the effectiveness of existing practices. All deviations observed during the audit and inspection need to be notified, and suitable corrective and preventive actions need to be implemented. The type of audit and inspections required to be performed by different stakeholders are listed, and all deviations observed during the audit and inspection need to be notified and suitable corrective and preventive actions need to be implemented.

Near Miss Recordings:

As a leading indicator we record the Near misses and appreciate the team for reporting, Near miss incidents are captured by team members as part of the safety rating system procedure. The recording of near miss incidents is a practice that involves taking counter-measures and updating the Hazard Identification and Risk Assessment (HIRA). The section head reviews these incidents to ensure corrective actions are taken. The recording of near miss incidents is crucial for identifying potential hazards and preventing future accidents.

Contractor Safety Management System (CSMS):

Our CSMS ensures contractor safety through a two-part process: (a) Pre-Qualification (PQ): Evaluating contractors before work begins. (b) Post-Contractor Management., and has processes like SOP on contractor selection & management, PQ form, contractor agreement sheet, procedure on erection & commissioning of capital goods & service activity, supplier appraisal/RA form and contractor performance rating & scoring system.

Many contractors have upgraded their H&S systems in line with Hero MotoCorp. Contractors are now privileged and get preference while bidding for other organizations. Their subcontractors have also gained on H&S. Their employees are more vocal than before, exchange ideas, make kaizen, are agile towards OH, and demonstrate good behavior on H&S.

Work Permit System:

The work permit system at Hero MotoCorp is a formal written system used to control certain types of work that are potentially hazardous. It specifies the work to be done and the precautions to be taken, allowing work to start only after safe procedures have been defined. The system provides a clear record of all foreseeable hazards that have been considered. The specific purposes of the work permit system include ensuring proper authorization of designated work, specifying the job and hazards involved, confirming work scope and verification of precautions, and providing a formal handover to ensure safety.

Evaluating OHS Performance and Progress

At Hero MotoCorp, we have established a comprehensive review framework to prioritize and integrate action plans with quantifiable targets to mitigate risks and evaluate progress in reducing or preventing health issues. Our review framework consists of multiple committees that ensure a thorough evaluation of OHS performance at various levels:

In addition to the multi-level review mechanism, our Environment, Health, and Safety (EHS) department plays a crucial role in monitoring and evaluating our OHS performance at all locations.

At Hero MotoCorp, we have identified potential hazards that could lead to emergencies and major accidents, including process hazards (chemical, temperature, cryogenic, and electric hazards), natural disasters, and environmental failures that could result in land, water, and air pollution. To mitigate these risks, we have developed a multi-faceted approach that includes:

Risk Assessment and Consequence Analysis:

Estimating the physical effects of potential accidents.

Onsite Action Plans:

We have developed detailed action plans that outline procedures and actions to be taken during an emergency, ensuring a swift and effective response.

Emergency Response Team:

This serves as the primary point of contact within the organization in the event of an accident or emergency.

Communication and Training:

We provide regular training and communication to all relevant personnel, including mock drills, tabletop exercise to familiarize employees with evacuation routes, assembly points, and emergency procedures.

We also conduct the mock drills with external agencies, government bodies like labor departments, Police , Fire departments, NDRF, SDRF etc.

Preparedness and Readiness:

Our comprehensive strategies and action plans enable us to respond quickly and effectively to emergencies, minimizing the risk of harm to people, the environment, and our operations.

Facilities equipped with trained & qualified Firemen with fire-fighting arrangements:

All our facilities are fully equipped with state-of-the-art firefighting arrangements, including:

We maintain a high standard of safety compliance and readiness to ensure the protection of all personnel and property.

This initiative is a strategic shift in industrial management where a plant’s safety responsibility extends beyond its physical gates. We organize time-to-time awareness programs for nearby societies, schools, industries on fire safety awareness, material handling, road safety etc.

We acknowledge that our responsibility to ensure Occupational Health and Safety (OHS) extends beyond our own facilities and into our entire value chain. To foster a culture of safety throughout our ecosystem, we have introduced rigorous OHS criteria into our procurement and contractual requirements.

To promote a culture of safety throughout our value chain, we have:

Shared Our Vision and Values:

Communicated our clear aim and vision to our value chain partners through Sustainable procurement guidelines and Supplier Code of Conduct , emphasizing the importance of upholding human rights, health, and safety values.

Capacity-Building Initiatives:

Organized regular capacity-building sessions with our value chain partners to share best practices in health and safety and encourage their implementation across various locations.

Collaborative Approach:

Fostered a collaborative environment where our value chain partners can learn from our experiences, share their own knowledge, and work together to enhance safety standards throughout the entire supply chain.

Engagement with Communities:

Our community engagement initiatives aim to empower individuals with the knowledge and skills necessary to prevent fires, respond to emergencies, and stay safe. By working together, we can create a culture of fire safety awareness and reduce the risk of fire-related incidents in our communities. Our goal is to make a positive impact and contribute to the well-being and safety of those around us.

We recognize the importance of educating all employees, workers, and contractors about workplace hazards, controls, and established Standard Operating Procedures (SOPs) to ensure a safe working environment.

We also organize many awareness programs for employees as well as for contract workers, such as hazard Hunt, Spot the hazard, chalta bolta quiz, poster competition, slogan competition, Ideathon wall etc.

We provide comprehensive information and training on:

Workplace Hazards:

Identifying potential hazards and risks associated with their work.

Controls and SOPs:

Understanding the measures in place to mitigate risks and following established procedures.

Reporting Mechanisms:

Knowing how to report incidents, near misses, and concerns, we are embracing digitalization and emerging technologies to enhance our safety programs.

Virtual Reality (VR) Training:

Creating immersive, computer-generated environments that simulate real-life scenarios, allowing employees to experience the consequences of non-adherence to safety guidelines. This innovative approach fosters a positive attitude towards established safety SOPs and practices.

Safety Gyms:

Setting up dedicated facilities at all locations, where employees can participate in live accident scenario simulations using fear simulation devices. This hands-on training enables employees to develop the skills and confidence to respond effectively in emergencies. We have defined our training modules to address the training needs of our stakeholders, few of these are:

At Hero MotoCorp, we firmly believe that our employees are our greatest asset, and their health and well-being are central to our success. We are committed to cultivating a holistic "culture of well-being" that actively promotes work-life integration and supports the diverse needs of our workforce.

Our approach is inclusive and considerate of all employees—across roles, genders, and abilities—ensuring that every individual receives the support they need to thrive personally and professionally.

Our Health & Wellness Management System is anchored in a comprehensive framework that integrates our Occupational Health and Safety Policy, local regulatory requirements, global best practices, and the World Health Organization's Healthy Workplace Model.

Health & Well-being Guidelines:

Hero MotoCorp is committed to ensuring the health, safety, and welfare of all its employees. We aim to establish a positive health and well-being culture that includes awareness, understanding, effective processes, and positive behavior by staff at all levels.

The health, safety, and welfare guidelines apply to all permanent employees and encompass physical, mental, psychosocial, spiritual, and financial aspects. The organization ensures that guidelines are accessible, wellness initiatives are communicated, and employees are encouraged to participate voluntarily. Feedback is actively sought for continuous improvement.

Occupational Health Guidelines:

Our Occupational Health Services are guided by our OH Manual, which complies with the Indian Factories Act 1948, State Factory rules, ISO 45001, and FSSAI regulations, ensuring a robust framework for employee health and safety.

Occupational Health Services:

We conduct pre-employment medical check-ups as per statutory and non-statutory requirements aligned with the job requirements. Periodical medical in-house check-ups with specific tests identified as per the risk assessment of the activities, employees working in different departments exposed to various occupational health hazards. We carry out most of these tests using in-house equipment, such as spirometers, audiometers, vision testers, and peak flow meters. Health assessments are conducted prior to an employee's return to work after recovery if being medically treated, and medical fitness certificates are verified, validated, and maintained as records.

Ergonomics and Industrial Hygiene:

We provide ergonomic workstations to prevent musculoskeletal problems by designing better workstations through ergonomic surveys and improvements and strengthening workplace monitoring. In FY25, we conducted a thorough ergonomic assessment at our Tirupati Plant to assess ergonomic-related improvements. We also conducted a qualitative industrial hygiene survey at our Halol Plant to assess the physical and chemical properties present in the work environment, such as lux, noise, dust, VOC, and CO.

Immunization and Biomedical Waste Management:

We immunize specific categories of employees per job requirements for specific protection under primary prevention protocol. As per statutory requirements, we manage biomedical waste generated as part of occupational health services.

Trainings for emergency response:

We organized the medical training of our medical staff as well as for our Emergency rescue team members to respond in case of emergency some of the training are as CPR, First aid, use of AED, Dog bite, Snakebite etc.

Angola

Angola

Argentina

Argentina

Bangladesh

Bangladesh

Bolivia

Bolivia

Colombia

Colombia

Costa Rica

Costa Rica

Dominican Republic

Dominican Republic

DRC

DRC

Ecuador

Ecuador

El Salvador

El Salvador

Ethiopia

Ethiopia

France

France

GCC

GCC

Great Britain

Great Britain

Guatemala

Guatemala

Guinea

Guinea

Guyana

Guyana

Haiti

Haiti

Honduras

Honduras

Italy

Italy

Kenya

Kenya

Madagascar

Madagascar

Mexico

Mexico

Myanmar

Myanmar

Nepal

Nepal

Nicaragua

Nicaragua

Nigeria

Nigeria

Panama

Panama

Peru

Peru

Philippines

Philippines

South Africa

South Africa

Spain

Spain

Sri Lanka

Sri Lanka

Tanzania

Tanzania

Trinidad

Trinidad

Turkey

Turkey

Uganda

Uganda

Zambia

Zambia

You’re officially a GoodLife Member

Free vehicle wash*

50% Discount on paint protection

Upto 10% discount on accessories

Discounted on joyride renewal

Welcome aboard!

Every ride just got more rewarding. Start exploring your exclusive perks and benefits today.

EXPLORE PLANS & BENEFITSI agree to the terms & condition and privacy policy

I agree to the terms & condition and privacy policy

Copyright Hero MotoCorp Ltd. 2026 . All Rights Reserved.